Environment

SQM is strongly committed to sustainable development. Consequently, the Company carries out its operations in harmony with the environment, ensuring that natural resources and inputs are used in a sustainable manner and minimizing the possible impacts of our production processes. We have developed solid know-how of the ecosystems surrounding our operations, which enables us to implement the prevention, mitigation, monitoring and control plans necessary to ensure that these environments are protected. We work relentlessly to continually improve all our processes and operations.

Protección Ambiental

En SQM trabajamos de manera consciente con el medioambiente, respetando la normativa ambiental vigente. Para nosotros es fundamental realizar nuestras operaciones en forma armónica y procurando mantener bajo control los posibles impactos, que producto de nuestro actuar se pudieran generar al medio ambiente y a las comunidades vecinas, como también resguardar el uso y sostenibilidad de los recursos naturales e insumos productivos. Nuestro trabajo lo desarrollamos de la mano de la Política de Desarrollo Sustentable, para minimizar los impactos ambientales, e incorporando en forma temprana la variable ambiental en el diseño de las operaciones, y así prevenir e implementar medidas de control y mitigación necesarias con un apropiado manejo de los residuos y emisiones.

Nuestras operaciones se ubican en zonas desérticas donde existe una escasa biodiversidad. A su vez, se observan ecosistemas de gran valor ecológico en algunos sectores cercanos a nuestras faenas. En estos sectores hemos implementado planes de protección, seguimiento, monitoreo y control, los cuales tiene un carácter permanente, para cuidar del entorno. La experiencia, nos ha permitido un vasto conocimiento sobre los ecosistemas cercanos a las operaciones, lo que ha permitido la elaboración e implementación de efectivos planes de prevención, mitigación y seguimiento. Todos nuestros proyectos son sometidos al Sistema de Evaluación de Impacto Ambiental. A diciembre de 2019 contamos con las autorizaciones ambientales de 62 proyectos, de éstos, 16 corresponden a SQM Nitratos S.A., 12 a SQM Industrial S.A., 14 a SQM S.A y 20 a SQM Salar S.A. De los 62 proyectos, 11 corresponden a Estudios de Impacto Ambiental y 51 a Declaraciones de Impacto Ambiental.

En SQM trabajamos de manera consciente con el medioambiente, respetando la normativa ambiental vigente. Para nosotros es fundamental realizar nuestras operaciones en forma armónica y procurando mantener bajo control los posibles impactos, que producto de nuestro actuar se pudieran generar al medio ambiente y a las comunidades vecinas, como también resguardar el uso y sostenibilidad de los recursos naturales e insumos productivos. Nuestro trabajo lo desarrollamos de la mano de la Política de Desarrollo Sustentable, para minimizar los impactos ambientales, e incorporando en forma temprana la variable ambiental en el diseño de las operaciones, y así prevenir e implementar medidas de control y mitigación necesarias con un apropiado manejo de los residuos y emisiones.

Nuestras operaciones se ubican en zonas desérticas donde existe una escasa biodiversidad. A su vez, se observan ecosistemas de gran valor ecológico en algunos sectores cercanos a nuestras faenas. En estos sectores hemos implementado planes de protección, seguimiento, monitoreo y control, los cuales tiene un carácter permanente, para cuidar del entorno. La experiencia, nos ha permitido un vasto conocimiento sobre los ecosistemas cercanos a las operaciones, lo que ha permitido la elaboración e implementación de efectivos planes de prevención, mitigación y seguimiento. Todos nuestros proyectos son sometidos al Sistema de Evaluación de Impacto Ambiental. A diciembre de 2019 contamos con las autorizaciones ambientales de 62 proyectos, de éstos, 16 corresponden a SQM Nitratos S.A., 12 a SQM Industrial S.A., 14 a SQM S.A y 20 a SQM Salar S.A. De los 62 proyectos, 11 corresponden a Estudios de Impacto Ambiental y 51 a Declaraciones de Impacto Ambiental. Agua

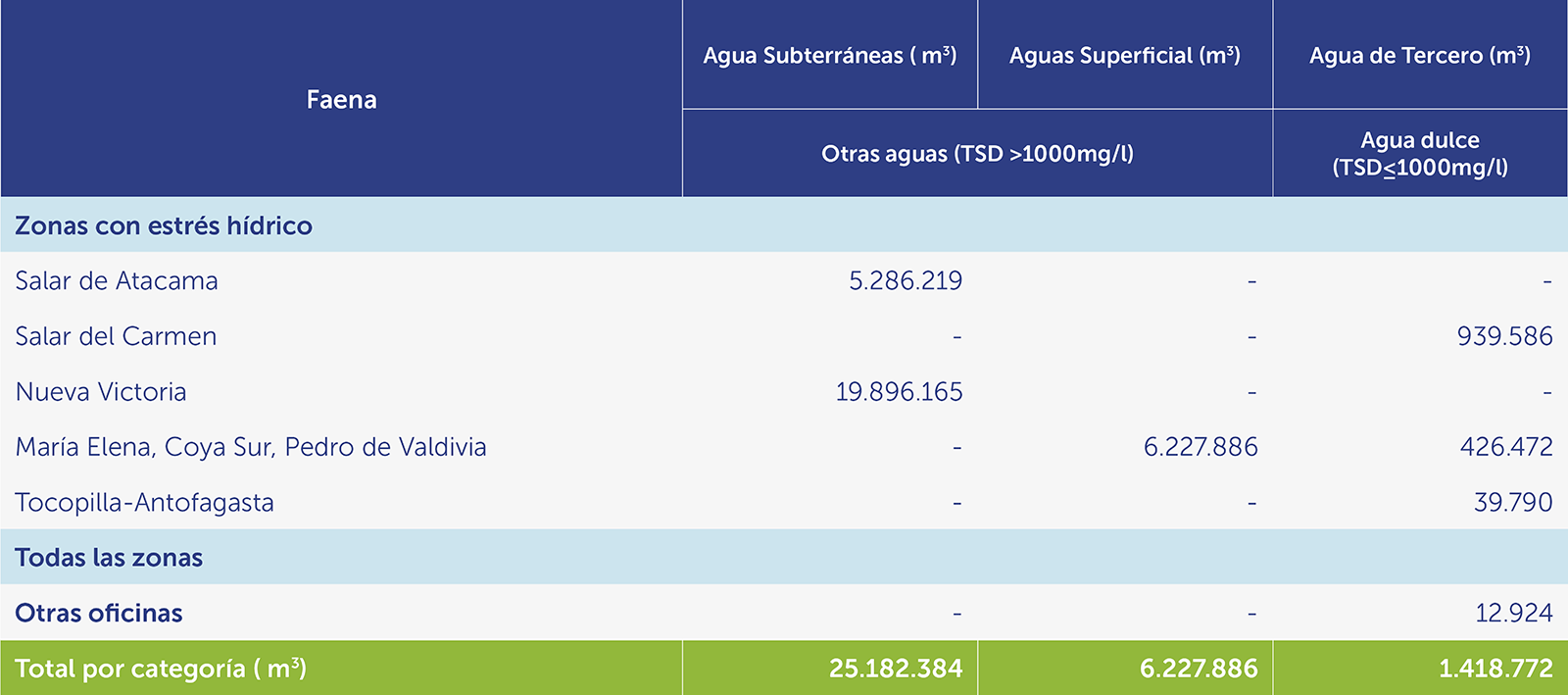

Para SQM es un tema relevante la utilización del agua en sus procesos productivos, dada la escasez de este recurso en los lugares donde se emplazan las operaciones, por lo cual es fundamental asegurar un manejo eficiente en los procesos productivos. Poseemos derechos de aprovechamiento de agua debidamente autorizados para las operaciones. El agua extraída corresponde a agua salada, subterránea y superficial.

En forma permanente, se comunica a la autoridad los consumos de agua de los procesos productivos. Además, se realizan estudios para identificar oportunidades de uso eficiente del recurso y se evalúan anualmente los indicadores de gestión en cada unidad operacional.

Para SQM es un tema relevante la utilización del agua en sus procesos productivos, dada la escasez de este recurso en los lugares donde se emplazan las operaciones, por lo cual es fundamental asegurar un manejo eficiente en los procesos productivos. Poseemos derechos de aprovechamiento de agua debidamente autorizados para las operaciones. El agua extraída corresponde a agua salada, subterránea y superficial.

En forma permanente, se comunica a la autoridad los consumos de agua de los procesos productivos. Además, se realizan estudios para identificar oportunidades de uso eficiente del recurso y se evalúan anualmente los indicadores de gestión en cada unidad operacional.

El uso eficiente del agua se logra mediante medidas como:

• Recirculación al proceso productivo de las aguas tratadas provenientes de nuestras plantas de tratamiento de agua servidas. Estas son recirculadas al proceso de las faenas de María Elena, Pedro de Valdivia, Coya Sur, Nueva Victoria y Salar de Atacama. La totalidad de las plantas de tratamiento de aguas servidas que maneja la compañía, son mantenidas y monitoreadas por empresas especializadas. • Recirculación de soluciones de proceso que reducen consumo de agua fresca. • Proveedores que ofrecen agua industrial proveniente del tratamiento de aguas domésticas, en la faena Salar del Carmen, el agua industrial suministrada proviene de los procesos de tratamiento de aguas servidas de la ciudad de Antofagasta, lo que permitido abastecer cerca del 84,6% del consumo de agua industrial requerida en el proceso de producción del carbonato e hidróxido de litio, en las instalaciones de Salar del Carmen. El consumo restante se realiza con agua comprada, proveniente de agua de mar desalinizada. La extracción de agua fresca para fines productivos es objeto de estrictas evaluaciones ambientales. Esto permite prevenir efectos sobre receptores ambientales relevantes como vegetación, flora y fauna asociada a los acuíferos y fuentes de agua superficial donde la empresa cuenta con derechos de extracción de agua. En conjunto con estos estudios, se diseñan y validan extensas modelaciones hidrogeológicas, bajo la supervisión de expertos nacionales e internacionales, a partir de las cuales se efectúa un permanente seguimiento del comportamiento esperado de los sistemas. Del total de los recursos subterráneos extraídos para Nueva Victoria durante el 2019 fueron reinyectados 802.625m3, como parte de la medida de mitigación contemplada por el proyecto “Pampa Hermosa” en el Salar de Llamara. Para optimizar el consumo agua realizamos la recirculación al proceso productivo de las aguas de descarte y tratadas provenientes de nuestras plantas de tratamiento de aguas servidas, reutilizando toda el agua. El agua reutilizada durante el 2019 se aproxima a 548.550 m3, correspondiente a una estimación operacional. Por su parte, los residuos líquidos domésticos provenientes de las oficinas de Antofagasta y del Puerto de Tocopilla, son dispuestos en la red de alcantarillado pública por lo que no se realizan vertidos de agua que afecten a la biodiversidad y hábitats protegidos. No generando vertidos de efluentes. Durante el año 2019 no se registraron derrames significativos en suelo y cuerpos de agua (superficial o subterráneos) dentro de las operaciones y faenas productivas de SQM.1.343.699 m³ DE AGUAS SERVIDAS FUERON REUTILIZADAS EN 2019.

Residuos

El manejo de residuos es fundamental para nuestra compañía por lo que éste es realizado de forma segura. Todas las empresas que realizan el transporte de los residuos y la disposición final de éstos cuentan con las autorizaciones correspondientes.

SQM ha desarrollado planes y procedimientos de manejo de residuos, tanto peligrosos como no peligrosos. Contamos con 8 bodegas de almacenamiento temporal de residuos peligrosos autorizados por la Secretaria Regional Ministerial de Salud, 6 bodegas autorizadas de almacenamiento temporal de residuos industriales no peligrosos y un lugar para la disposición de los residuos domésticos que se generan en las operaciones.

El 82% de los residuos industriales peligrosos que se generaron en las operaciones en 2019 fueron enviados a disposición final, en transportes autorizados, la diferencia se recicla o son utilizados para recuperación energética. El transporte de residuos peligrosos se realiza según la normativa vigente en Chile.

Los residuos sólidos domiciliarios son manejados en todas las operaciones y campamentos, y su disposición se realiza en rellenos sanitarios autorizados.

Durante el 2019 no hubo generación de residuos peligrosos cuya disposición final y/o tratamiento haya sido fuera de Chile y el 18% de los residuos peligrosos que se generaron en las operaciones fueron recuperados como combustible alternativo por empresas externas.

Como compañía se busca dar prioridad al reciclaje o la reutilización, siendo nuestra última opción la eliminación de residuos, utilizando empresas autorizadas para esta gestión.

Es importante señalar que los productos de SQM se venden mayoritariamente a granel, por lo que el uso de envases y embalajes es menor, minimizando la generación de futuros residuos.

El manejo de residuos es fundamental para nuestra compañía por lo que éste es realizado de forma segura. Todas las empresas que realizan el transporte de los residuos y la disposición final de éstos cuentan con las autorizaciones correspondientes.

SQM ha desarrollado planes y procedimientos de manejo de residuos, tanto peligrosos como no peligrosos. Contamos con 8 bodegas de almacenamiento temporal de residuos peligrosos autorizados por la Secretaria Regional Ministerial de Salud, 6 bodegas autorizadas de almacenamiento temporal de residuos industriales no peligrosos y un lugar para la disposición de los residuos domésticos que se generan en las operaciones.

El 82% de los residuos industriales peligrosos que se generaron en las operaciones en 2019 fueron enviados a disposición final, en transportes autorizados, la diferencia se recicla o son utilizados para recuperación energética. El transporte de residuos peligrosos se realiza según la normativa vigente en Chile.

Los residuos sólidos domiciliarios son manejados en todas las operaciones y campamentos, y su disposición se realiza en rellenos sanitarios autorizados.

Durante el 2019 no hubo generación de residuos peligrosos cuya disposición final y/o tratamiento haya sido fuera de Chile y el 18% de los residuos peligrosos que se generaron en las operaciones fueron recuperados como combustible alternativo por empresas externas.

Como compañía se busca dar prioridad al reciclaje o la reutilización, siendo nuestra última opción la eliminación de residuos, utilizando empresas autorizadas para esta gestión.

Es importante señalar que los productos de SQM se venden mayoritariamente a granel, por lo que el uso de envases y embalajes es menor, minimizando la generación de futuros residuos. Emisiones

Controlamos las emisiones en todas nuestras operaciones, esto se realiza mediante una detallada predicción de los efectos ambientales identificados, la instalación e implementación de equipos de abatimiento y un adecuado seguimiento de las emisiones.

Mantenemos estaciones meteorológicas, esenciales para monitorear los procesos de evaporación solar en las operaciones. Además, la compañía cuenta con planes de seguimiento ambiental implementados, como parte de ellos, se realizan mediciones isocinéticas a las salidas de chimeneas de los equipos, que forman parte del proceso productivo como secadores y calderas.

SQM ha realizado una ardua labor para manejar y vigilar las emisiones de material particulado MP10, contamos con una vasta red de monitoreo de la calidad del aire en la localidad de María Elena, y somos partes de la red de monitoreo de Calidad del Aire en Tocopilla.

Con respecto a los Planes de Descontaminación Atmosféricos para MP 10 que se realizan en estas localidades, la compañía ha implementado una amplia gama de medidas que le han permitido cumplir con los compromisos de control y reducción de las emisiones:

• En María Elena, desde el 2007 a la fecha, se ha logrado reducir las emisiones de MP10 en 97,8% las emisiones en la Planta de Producción Maria Elena. La disminución es producto de cambios operacionales implementados, los cuales han permitido mejorar significativamente la calidad del aire en la localidad cumpliendo con la norma diaria y anual de MP10. • Para la ciudad de Tocopilla, las emisiones de MP10 generadas por las operaciones del puerto de SQM son menores frente a otras fuentes en el lugar. En el marco del Plan de Descontaminación Atmosférico de Tocopilla, se han cumplido los compromisos y ejecutado todas las medidas necesarias para mitigar sus emisiones.

Durante el 2019, la emisión de MP10 de las operaciones del Puerto de SQM fue de 4,56 ton., logrando una reducción de 37% de MP10 emitido en relación al año 2007. Al comparar estos resultados con los obtenidos en 2019 la reducción es de 24% bajo lo comprometido en el Plan de Descontaminación.

Controlamos las emisiones en todas nuestras operaciones, esto se realiza mediante una detallada predicción de los efectos ambientales identificados, la instalación e implementación de equipos de abatimiento y un adecuado seguimiento de las emisiones.

Mantenemos estaciones meteorológicas, esenciales para monitorear los procesos de evaporación solar en las operaciones. Además, la compañía cuenta con planes de seguimiento ambiental implementados, como parte de ellos, se realizan mediciones isocinéticas a las salidas de chimeneas de los equipos, que forman parte del proceso productivo como secadores y calderas.

SQM ha realizado una ardua labor para manejar y vigilar las emisiones de material particulado MP10, contamos con una vasta red de monitoreo de la calidad del aire en la localidad de María Elena, y somos partes de la red de monitoreo de Calidad del Aire en Tocopilla.

Con respecto a los Planes de Descontaminación Atmosféricos para MP 10 que se realizan en estas localidades, la compañía ha implementado una amplia gama de medidas que le han permitido cumplir con los compromisos de control y reducción de las emisiones:

• En María Elena, desde el 2007 a la fecha, se ha logrado reducir las emisiones de MP10 en 97,8% las emisiones en la Planta de Producción Maria Elena. La disminución es producto de cambios operacionales implementados, los cuales han permitido mejorar significativamente la calidad del aire en la localidad cumpliendo con la norma diaria y anual de MP10. • Para la ciudad de Tocopilla, las emisiones de MP10 generadas por las operaciones del puerto de SQM son menores frente a otras fuentes en el lugar. En el marco del Plan de Descontaminación Atmosférico de Tocopilla, se han cumplido los compromisos y ejecutado todas las medidas necesarias para mitigar sus emisiones.

Durante el 2019, la emisión de MP10 de las operaciones del Puerto de SQM fue de 4,56 ton., logrando una reducción de 37% de MP10 emitido en relación al año 2007. Al comparar estos resultados con los obtenidos en 2019 la reducción es de 24% bajo lo comprometido en el Plan de Descontaminación.

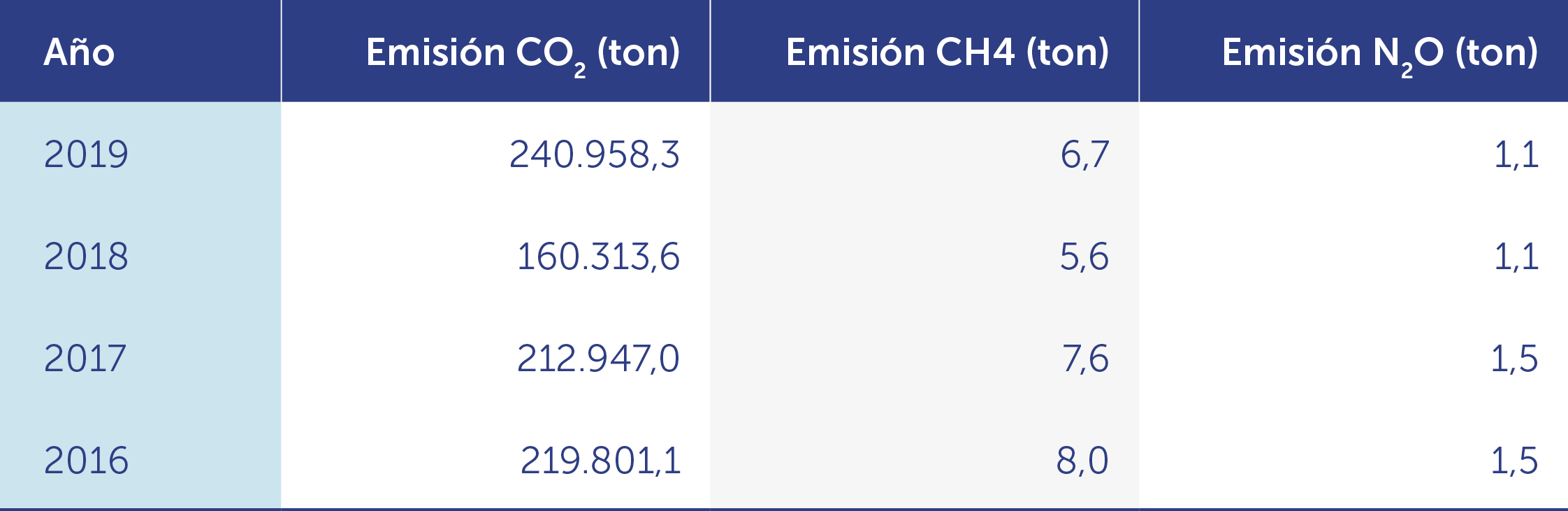

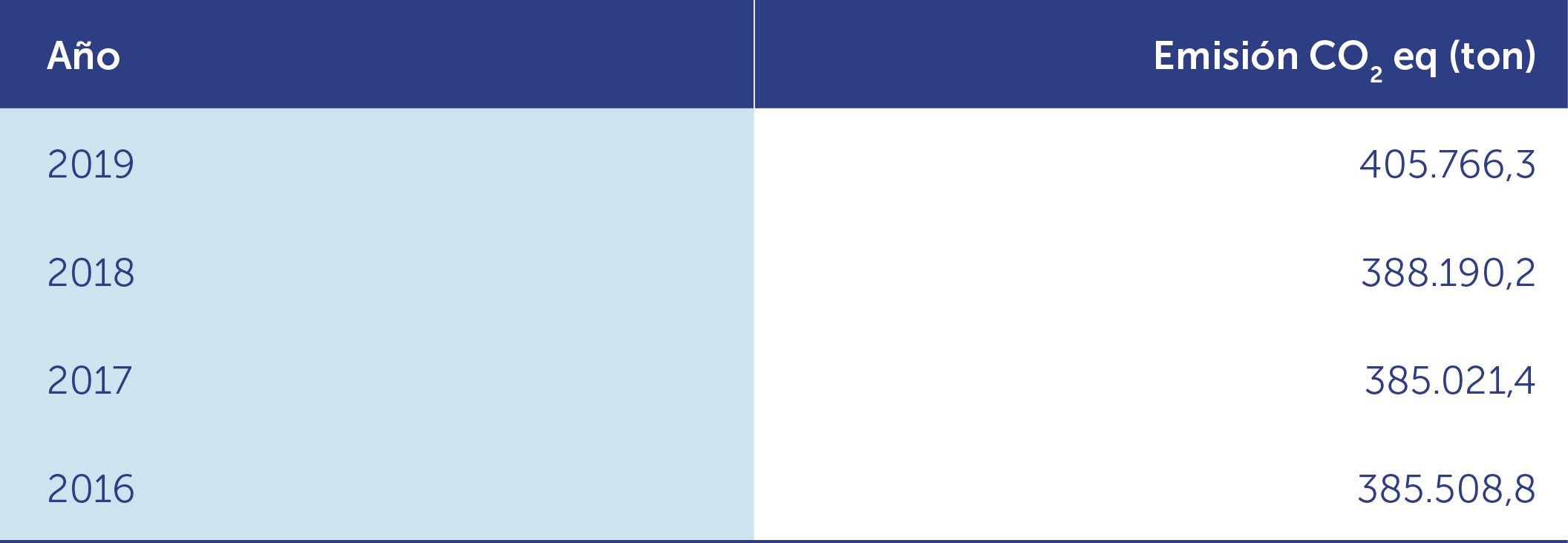

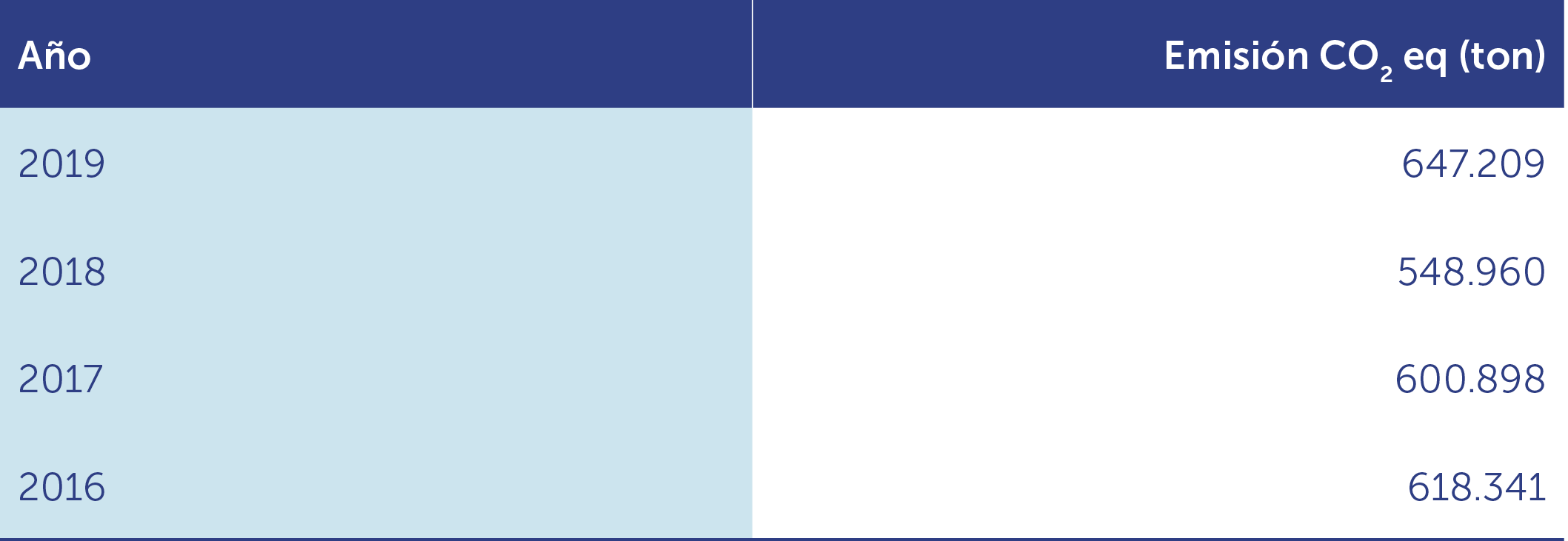

GASES DE EFECTO INVERNADERO (GEI)

SQM estima el total de su Huella de Carbono asociada a la suma de sus procesos productivos y también en forma separada para varios de sus productos. La estimación de GEI considera desde los procesos extractivos del mineral hasta la obtención del producto terminado.INTENSIDAD GEI (ALCANCE 1 Y 2)

Del cálculo realizado, hemos estimado que las emisiones de GEI para 2017, 2018 y 2019, se mantienen inferiores a un millón de toneladas de CO2 equivalente (CO2 eq) para cada año.

En el 2019 la emisión total de GEI fue de 647.209 ton CO2 eq. Desglosando en 241.443ton CO2 eq (Alcance 1) y 405.766 ton CO2 eq (Alcance 2), incluye emisiones CO2, emisiones de CH4 y las emisiones N2O. Las emisiones GEI son estimadas con la metodología IPCC (IPCC Guidelines for National Greenhouse Gas Inventories), y los factores utilizados para la energía eléctrica corresponde a los publicados en sitio Comisión Nacional de Energía. Se utiliza los factores de acuerdo al Sistema Interconectado del Norte Grande, SING, y Sistema Interconectado Central, SIC y considera el cálculo de:

Del cálculo realizado, hemos estimado que las emisiones de GEI para 2017, 2018 y 2019, se mantienen inferiores a un millón de toneladas de CO2 equivalente (CO2 eq) para cada año.

En el 2019 la emisión total de GEI fue de 647.209 ton CO2 eq. Desglosando en 241.443ton CO2 eq (Alcance 1) y 405.766 ton CO2 eq (Alcance 2), incluye emisiones CO2, emisiones de CH4 y las emisiones N2O. Las emisiones GEI son estimadas con la metodología IPCC (IPCC Guidelines for National Greenhouse Gas Inventories), y los factores utilizados para la energía eléctrica corresponde a los publicados en sitio Comisión Nacional de Energía. Se utiliza los factores de acuerdo al Sistema Interconectado del Norte Grande, SING, y Sistema Interconectado Central, SIC y considera el cálculo de:

ALCANCE 1: EMISIONES DIRECTAS POR CONSUMO DE COMBUSTIBLE:

ALCANCE 2: EMISIONES INDIRECTAS POR CONSUMO DE ENERGÍA ELÉCTRICA:

LOS RESULTADOS DE ESTA CUANTIFICACIÓN FUERON:

Energía

SSQM utiliza un alto porcentaje de energía solar, la que es fundamental en los procesos productivos de las pozas de evaporación solar de las faenas: Coya Sur, Nueva Victoria y Salar de Atacama. Esta forma de operar implica una ventaja frente a otros procesos y sólo es posible debido a que en el Desierto de Atacama, donde se ubican las operaciones de SQM, existen los más altos niveles de radiación solar, provocando altas tasa de evaporación, facilitando los procesos de concentración de sales en las pozas, durante todo las estaciones del año y de forma continua.

Las operaciones de SQM obtienen su energía eléctrica del Sistema Eléctrico Nacional (SEN) y de combustibles priorizando el uso de aquellas alternativas más limpias, como petróleo y gas natural. Alrededor de 4.000 ha. aproximadamente, corresponden a pozas solares que permiten capturar energía solar. La energía solar equivale a un 92 % de la energía requerida en las operaciones.

SSQM utiliza un alto porcentaje de energía solar, la que es fundamental en los procesos productivos de las pozas de evaporación solar de las faenas: Coya Sur, Nueva Victoria y Salar de Atacama. Esta forma de operar implica una ventaja frente a otros procesos y sólo es posible debido a que en el Desierto de Atacama, donde se ubican las operaciones de SQM, existen los más altos niveles de radiación solar, provocando altas tasa de evaporación, facilitando los procesos de concentración de sales en las pozas, durante todo las estaciones del año y de forma continua.

Las operaciones de SQM obtienen su energía eléctrica del Sistema Eléctrico Nacional (SEN) y de combustibles priorizando el uso de aquellas alternativas más limpias, como petróleo y gas natural. Alrededor de 4.000 ha. aproximadamente, corresponden a pozas solares que permiten capturar energía solar. La energía solar equivale a un 92 % de la energía requerida en las operaciones.

91,1% DEL TOTAL DE LA ENERGÍA EMPLEADA EN LAS OPERACIONES CORRESPONDE A ENERGÍA SOLAR

CONSUMO DE ENERGÍA 2019

Primer Taller de Mantenimiento

El norte de Chile es reconocido por su alta de radiación solar y bajas precipitaciones. Estos aspectos impulsaron a el equipo de la Superintendencia de Mantención Mina de Salar de Atacama, para generar un inédito proyecto que busca utilizar la energía solar para la ejecución de las operaciones del Taller de Mantención de una manera más amigable y respetuosa con el medioambiente y las comunidades de nuestra zona.

La idea nació de los trabajadores, quienes se desafiaron a generar proyectos tendientes a promover el cuidado de nuestro entorno.

La innovadora idea busca co-generar energías limpias dentro de dicho taller, a través de la tecnología ‘On Grid’, sistema que se encuentra conectado a la red eléctrica y que -al mismo tiempo- busca autogenerar energía mediante un sistema de paneles solares. Gracias a su funcionamiento, se produce el 60% de la energía requerida por el taller durante el día, a través de los paneles instalados en su techumbre.

El aporte de energía de los paneles alcanza los 68 kwh/día, con una producción anual de 19 mega watts, los cuales se generan desde las 7:00 hasta las 19:00 horas, periodo con mayor radicación del sol. Luego de ese horario, el taller comienza a operar conectada a la red eléctrica hasta las 06:59 a.m., donde nuevamente el sistema de paneles fotovoltaicos alimenta las instalaciones.

El norte de Chile es reconocido por su alta de radiación solar y bajas precipitaciones. Estos aspectos impulsaron a el equipo de la Superintendencia de Mantención Mina de Salar de Atacama, para generar un inédito proyecto que busca utilizar la energía solar para la ejecución de las operaciones del Taller de Mantención de una manera más amigable y respetuosa con el medioambiente y las comunidades de nuestra zona.

La idea nació de los trabajadores, quienes se desafiaron a generar proyectos tendientes a promover el cuidado de nuestro entorno.

La innovadora idea busca co-generar energías limpias dentro de dicho taller, a través de la tecnología ‘On Grid’, sistema que se encuentra conectado a la red eléctrica y que -al mismo tiempo- busca autogenerar energía mediante un sistema de paneles solares. Gracias a su funcionamiento, se produce el 60% de la energía requerida por el taller durante el día, a través de los paneles instalados en su techumbre.

El aporte de energía de los paneles alcanza los 68 kwh/día, con una producción anual de 19 mega watts, los cuales se generan desde las 7:00 hasta las 19:00 horas, periodo con mayor radicación del sol. Luego de ese horario, el taller comienza a operar conectada a la red eléctrica hasta las 06:59 a.m., donde nuevamente el sistema de paneles fotovoltaicos alimenta las instalaciones.

Impulsando la Eletromovilidad

Con la finalidad de potenciar y promover la utilización de energías limpias, SQM junto a Copec inauguraron el primer eco cargador eléctrico de Sudamérica, en la Región de Antofagasta, en su faena Salar del Carmen, el que busca aportar al desarrollo sustentable y al cuidado del medio ambiente, disminuyendo las emisiones de dióxido de carbono (CO2) y gases de efecto invernadero (GEI).

La iniciativa va a contribuir a las políticas públicas de energía que se encuentra promoviendo el gobierno como “La Ruta Energética 2018 – 2022”, la cual tiene como fin modernizar la matriz energética de Chile y que, dentro de sus desafíos, incluye: aumentar la oferta de vehículos eléctricos, ampliar la disposición de estaciones de carga, promover proyectos de investigación sobre electromovilidad y participar de diversas instancias de colaboración público-privadas.

Este sistema de energía sustentable no requiere estar conectado a la red eléctrica nacional (Off Grid), pues opera las 24 horas, durante los 365 días del año y se alimenta 100% de energía solar, gracias a sus 46 paneles ubicados con una inclinación de 15° en los 96 metros cuadrados destinados para su funcionamiento. El sistema absorbe la energía generada por el sol -mediante su pequeña planta fotovoltaicala guarda en las baterías de litio dispuestas en el sistema para que, finalmente, sea distribuida a través de un cargador eléctrico que cuenta con un controlador inteligente.

Próximamente, la electrolinera solar será una realidad en otras de nuestras faenas como Antofagasta, María Elena, Tocopilla y Salar de Atacama.

Cabe mencionar, que uno de los aspectos más importantes de este hito operacional será el reemplazo, a mediano plazo, de un porcentaje de la flota de vehículos a combustión diésel de SQM. Ejemplo de aquello es la experiencia del área de Bodega de Salar del Carmen, que utiliza dos modelos de furgones eléctricos para sus tareas cotidianas.

Con la finalidad de potenciar y promover la utilización de energías limpias, SQM junto a Copec inauguraron el primer eco cargador eléctrico de Sudamérica, en la Región de Antofagasta, en su faena Salar del Carmen, el que busca aportar al desarrollo sustentable y al cuidado del medio ambiente, disminuyendo las emisiones de dióxido de carbono (CO2) y gases de efecto invernadero (GEI).

La iniciativa va a contribuir a las políticas públicas de energía que se encuentra promoviendo el gobierno como “La Ruta Energética 2018 – 2022”, la cual tiene como fin modernizar la matriz energética de Chile y que, dentro de sus desafíos, incluye: aumentar la oferta de vehículos eléctricos, ampliar la disposición de estaciones de carga, promover proyectos de investigación sobre electromovilidad y participar de diversas instancias de colaboración público-privadas.

Este sistema de energía sustentable no requiere estar conectado a la red eléctrica nacional (Off Grid), pues opera las 24 horas, durante los 365 días del año y se alimenta 100% de energía solar, gracias a sus 46 paneles ubicados con una inclinación de 15° en los 96 metros cuadrados destinados para su funcionamiento. El sistema absorbe la energía generada por el sol -mediante su pequeña planta fotovoltaicala guarda en las baterías de litio dispuestas en el sistema para que, finalmente, sea distribuida a través de un cargador eléctrico que cuenta con un controlador inteligente.

Próximamente, la electrolinera solar será una realidad en otras de nuestras faenas como Antofagasta, María Elena, Tocopilla y Salar de Atacama.

Cabe mencionar, que uno de los aspectos más importantes de este hito operacional será el reemplazo, a mediano plazo, de un porcentaje de la flota de vehículos a combustión diésel de SQM. Ejemplo de aquello es la experiencia del área de Bodega de Salar del Carmen, que utiliza dos modelos de furgones eléctricos para sus tareas cotidianas.

Trabajadores de SQM se Capacitan en Medio Ambiente

Uno de los principales compromisos de nuestra compañía es velar para que las operaciones se lleven a cabo de manera respetuosa con su medio ambiente y vecinos, garantizando así, el cumplimiento de la normativa vigente. Con esta premisa, trabajadores de las operaciones de Salar de Atacama y de las áreas de Comunidades y Medio Ambiente e Hidrogeología, participaron de una capacitación enfocada a conocer las diversas iniciativas que nos permiten realizar nuestro trabajo en armonía con el entorno, previniendo los posibles impactos asociados a nuestro quehacer.

La capacitación, busca generar un espacio de conversación sobre diversos temas de interés, como la formación geológica de la cuenca del Salar de Atacama, el Plan de Extracción Autorizado según la Resolución de Calificación Ambiental (RCA); los aspectos más significantes de la institucionalidad ambiental chilena; la evaluación de Proyectos según SEA (Servicio de Evaluación Ambiental) y los proyectos aprobados en Salar de Atacama.

El principal objetivo es entregar conocimientos sólidos para una adecuada toma de decisiones a nivel productivo, entender cómo influyen las decisiones que tomamos cada día, generando sinergias entre la cultura del cuidado ambiental.

Uno de los principales compromisos de nuestra compañía es velar para que las operaciones se lleven a cabo de manera respetuosa con su medio ambiente y vecinos, garantizando así, el cumplimiento de la normativa vigente. Con esta premisa, trabajadores de las operaciones de Salar de Atacama y de las áreas de Comunidades y Medio Ambiente e Hidrogeología, participaron de una capacitación enfocada a conocer las diversas iniciativas que nos permiten realizar nuestro trabajo en armonía con el entorno, previniendo los posibles impactos asociados a nuestro quehacer.

La capacitación, busca generar un espacio de conversación sobre diversos temas de interés, como la formación geológica de la cuenca del Salar de Atacama, el Plan de Extracción Autorizado según la Resolución de Calificación Ambiental (RCA); los aspectos más significantes de la institucionalidad ambiental chilena; la evaluación de Proyectos según SEA (Servicio de Evaluación Ambiental) y los proyectos aprobados en Salar de Atacama.

El principal objetivo es entregar conocimientos sólidos para una adecuada toma de decisiones a nivel productivo, entender cómo influyen las decisiones que tomamos cada día, generando sinergias entre la cultura del cuidado ambiental.